how IS the A/F coating performing?

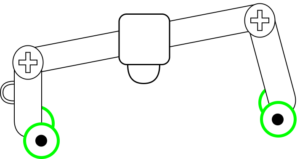

Our BFID is an on-board inspection device that empowers the owner with autonomy for ad-hoc underwater inspections regardless of the vessel's position or diver availability

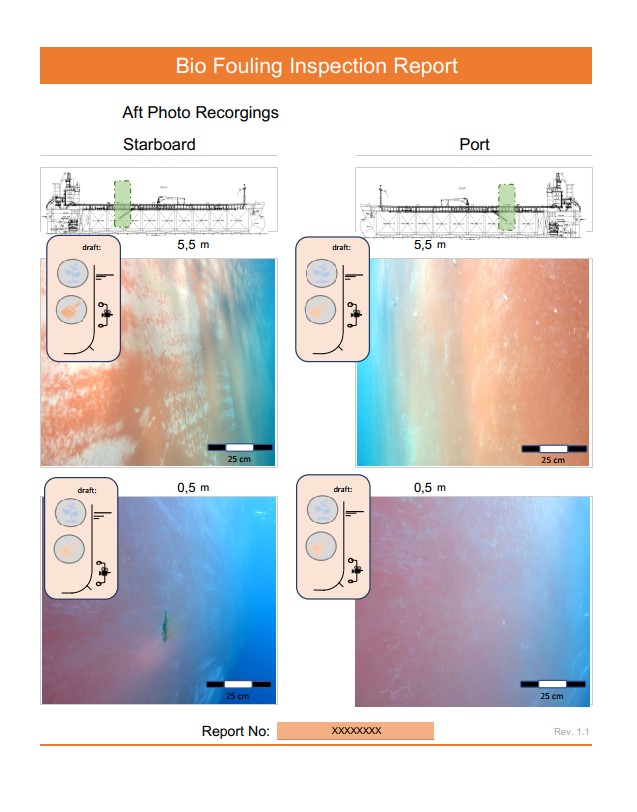

Biofouling Inspection findings, quantified by our in-house AI.

Deploy ad-hoc

Order the crew to deploy the BFID regardless of the vessel’s position

Collect findings

Send the data aquired by the BFID to Naval Plus via email

Get the report in 24h

Receive proposed action plan report, based on actual condition findings

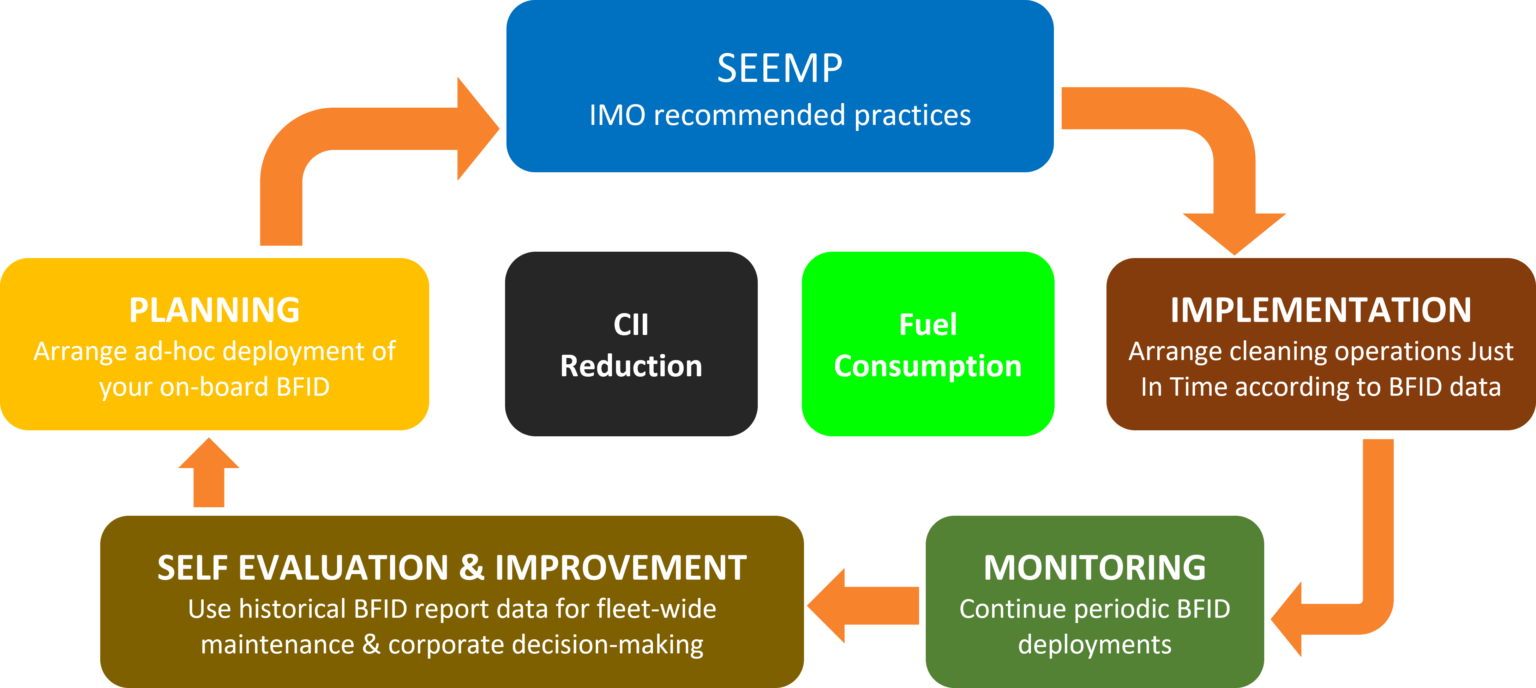

Proactively & Periodically deploy your BFID to compliment the asset's SEEMP

Monitor your fleet

Use your onboard BFID to make strategic fleet-wide decisions

Inspect ad-hoc

Arrange autonomous u/w inspections using your own crew.

Detailed high definition photos are provided for the entire vertical side up-to bilge keel level

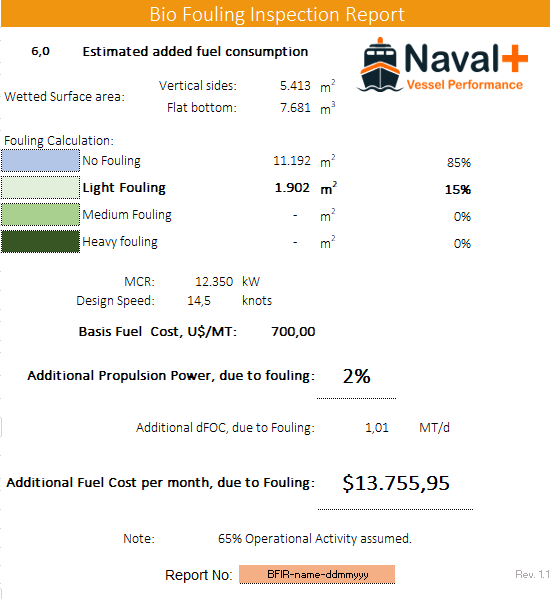

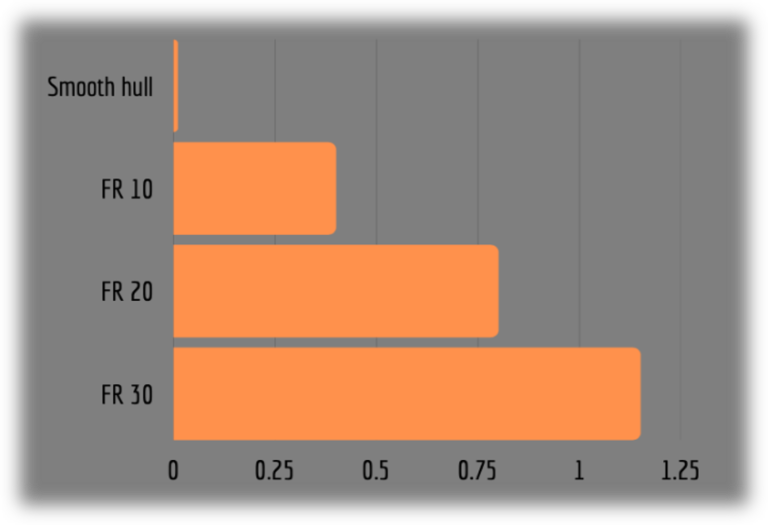

Our inhouse AI is specifically developed to quantify the BFID data, with respect to the asset’s current FR and correlate the respective fuel penalty.

Asset biofouling pressure is recorded through time, allowing CP clause(s) to be substantiated and effective u/w planned maintenance to be applied.

Deliverables | Reporting

Proactive periodic deployment of our BFID will deliver valuable data that can greatly assist the vessel’s SEEMP achieve the CII imposed by the IMO.

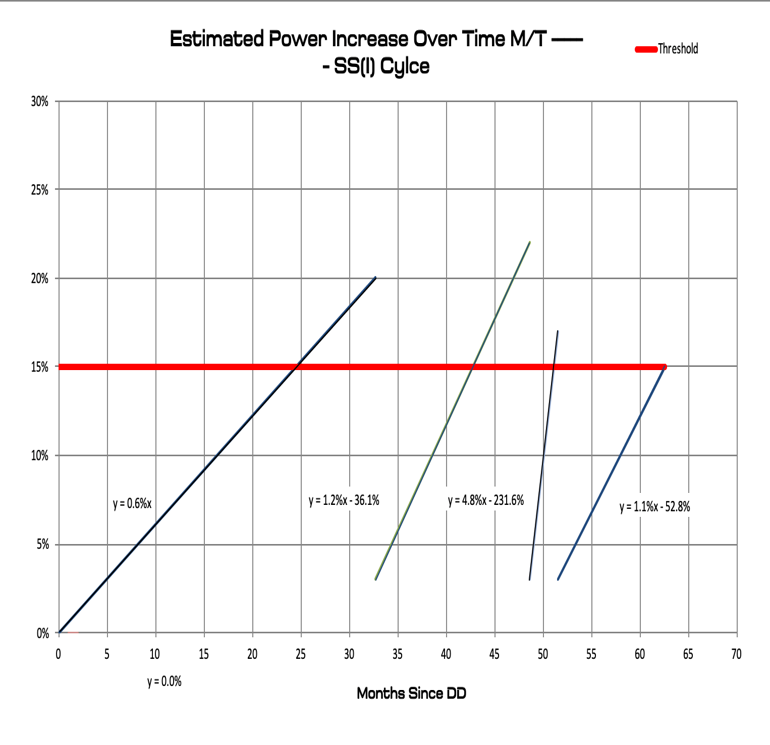

Fouling Increase Rate

By utilizing the BFID’s immediate deployment capability the operator can closely monitor the vessel’s Fouling Rate (FR) and act in the most cost effective manner, through informed decision making by arranging “Just In time” underwater cleaning, well aligned with IMO best practices.

-

Improve planning and execution of u/w hull maintenance

-

Verify the quality of hull cleaning service performed

-

Monitor a/f coating performance

-

Eliminate unecessary inspection costs

-

Make fleet-wide strategic decisions

by Proactively incorporating the BFID in the vessel's SEEMP

Ship energy efficiency management plan

Goal: Minimize Fuel & GHG emissions penalty

Continuous Hull Monitoring – eliminates operational dependance and underwater inspection cost(s) associated with third party services.

Periodical Biofouling Status Reporting, compliments existing Biofouling Managemet Plan, providing data driven decision making capabilities.

Reduction in Fuel Consumption and respective GHG emission, is achieved through continuous monitoring capabilities.

Exclusive Partners